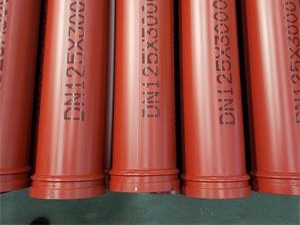

| Concrete Pump Pipe |

|---|

| Made by Jewinnerparts |

| Material: ST52/55Mn/65Mn/other materials |

| Technical: Hardened/Heat treatment |

| Wall Thickness: 3-10mm Main Length:3000mm/3048mm OD:76-140mm |

| Flange: SK/HD/MF/ZX/Others |

Why Us

|

Concrete Pump Heat Treated Reducer

Concrete Pump Heat Treated Reducer US$72.87-88.24 GET BETTER QUOTE [...]

Hammer Shut off Valve

HD and SK Hammer Shut off Valve US$72.88-117.78 GET BETTER QUOTE [...]

Steel Pipe for Concrete Spraying Machine

Steel Pipe for Concrete Spraying Machine This pipe is special for the Europe [...]

Putzmeister Swing-out Elbow without Port

Putzmeister Swing-out Elbow without Port US$277.98-298.79 GET BETTER QUOTE [...]

Schwing MF Concrete Delivery Pipes

Schwing MF Concrete Delivery Pipes GET BETTER QUOTE [...]

Putzmeister ZX Concrete Delivery Pipe

Putzmeister ZX Concrete Delivery Pipe is a pipeline for conveying concrete under high [...]

Reducing Elbow

Reducing Elbow US$46.98-76.88 GET BETTER QUOTE Our reducing [...]

Concrete Pump Pipe Elbows

Concrete Pump Pipe Elbows US$20.47-189.77 GET BETTER QUOTE [...]

Concrete Steel Reducer Pipes

Concrete Steel Reducer Pipes US$36.96-99.7 GET BETTER QUOTE [...]

Heavy Duty Pipe Bends

Heavy Duty Pipe Bends US$29.76-57.02 GET BETTER QUOTE [...]

Mobile Concrete Pumps Boom Pipe- 3000mm DN125, Twin-Wall

Mobile Concrete Pumps Boom Pipe- 3000mm DN125, Twin-Wall Description [...]

Concrete Pumping Machine Boom Pipe- 3000mm DN125, Twin-Wall

Concrete Pumping Machine Boom Pipe- 3000mm DN125, Twin-Wall Description [...]

Concrete Pump Truck Boom Pipe- 3000mm DN117, Twin-Wall, JEWINNERPARTS

Concrete Pump Truck Boom Pipe- 3000mm DN117, Twin-Wall, JEWINNERPARTS [...]

Concrete Placing Boom Pipe-Deck Pipe 3000mm DN125, Hardened-Single

Concrete Placing Boom Pipe-Deck Pipe 3000mm DN125, Hardened-Single (JEWINNERPARTS) [...]

Boom Pump Truck Pipe-3000mm DN125-Hardened-Single-Wall

Boom Pump Truck Pipe-3000mm DN125 JEWINNERPARTS-Hardened-Single-Wall Description Our boom [...]

Stationary Concrete Pump Pipe -5″ X 10′ X 6.35mm, HD Ends,More Tough

Stationary Concrete Pump Pipe -5″ X 10′ X 6.35mm [...]

Concrete Pump Trailer Pipe -5″ X 10′ X 4.5mm HD Ends,JEWINNERPRTS

Concrete Pump Trailer Pipe -5″ X 10′ X 4.5mm [...]

Stationary Pump Pipe -5″ X 10′ X 4mm Wall Thickness, HD Ends,JEWINNERPRTS

Stationary Pump Pipe -5″ X 10′ X 4mm HD [...]

Concrete Ground Pump Steel Pipe 4″ X 10′ X 3mm Wall Thickness, HD Ends

Concrete Ground Pump Steel Pipe 4″ X 10′ X 3mm Wall [...]

Placing Boom Pipe-3″ HD Pipe X 3048mmX 3mm Wall thckness,HD Flange

Concrete Ground Pump Steel Pipe 4″ X 10′ X [...]

Trailer Pumps Pipe-2.5″ HD Pipe X 120″ 3mm W/Chamfered Flange Ends, 11 Gauge/3mm

Trailer Pumps Pipe-2.5″ HD Pipe X 120″ 3mm W/Chamfered [...]

Shotcrete Pump Pipe -2″ HD Pipe X 120″ 3mm W/ HD Flange Ends

Shotcrete Pump Pipe -2″ HD Pipe X 120″ 3mm [...]

We are a leading exporter and supplier of concrete pump pipes for our clients. Our pipes are tested and manufactured as per the client’s requirements. Customize production is also available

Hot Selling Pipes Specifications

| Lay Down Pipe | |||||||||

| DN | Specification | Flange | Material | Weight | |||||

| (in./mm) | mm | Kg | |||||||

| 2.0″/DN50 | 57*3.0*3048 | HD | ST52 | 13.17 | |||||

| 2.0″/DN50 | 57*3.5*3048 | HD | ST52 | 15.07 | |||||

| 2.5″/DN63 | 70*3.0*3048 | HD | ST52 | 16.62 | |||||

| 2.5″/DN63 | 70*3.5*3048 | HD | ST52 | 18.99 | |||||

| 3″/DN76 | 82*3.0*3048 | HD | ST52 | 19.93 | |||||

| 3″/DN76 | 82*3.5*3048 | HD | ST52 | 22.72 | |||||

| 3″/DN76 | 82*4*3048 | HD | ST52 | 26.01 | |||||

| 5″/DN125 | 133*3.0*3048 | HD | ST52 | 29.26 | |||||

| 5″/DN125 | 133*3.5*3048 | HD | ST52 | 34.53 | |||||

| 5″/DN125 | 133*4.0*3048 | HD | ST52 | 39.69 | |||||

| 5″/DN125 | 133*4.5*3048 | HD | ST52 | 43.78 | |||||

| 5″/DN125 | 133*3.0*3048 | HD | ST52 | 55.73 | |||||

| 5″/DN125 | 140*3.0*3048 | HD | ST52 | 65 |

| Concrete Pump Boom Pipe | Single Wall | ||||

| DN | Specification | Flange | Material | Weight | |

| (in./mm) | mm | Kg | |||

| 5.5″/DN125 | 133*4.0*3000 | SK | ST52 | 39.65 | |

| 5.5″/DN125 | 133*4.5*3000 | SK | ST52 | 43.7 | |

| 5.5″/DN125 | 133*5*3000 | SK | ST52 | 48.26 | |

| Concrete Pump Boom Pipe | Hardened Single Wall | ||||

| DN | Specification | Flange | Material | Weight | |

| (in./mm) | mm | ||||

| 5.5″/DN125 | 133*4.0*3000 | SK | 55/65Mn | 44.4 | |

| 5.5″/DN125 | 133*4.5*3000 | SK | 55/65Mn | 44.7 | |

| 5.5″/DN125 | 133*5*3000 | SK | 55/65Mn | 50.6 | |

| Concrete Pump Boom Pipe | Heat Treatment Twin Wall | ||||

| DN | Specification | Wall | Flange | Material | Weight |

| (in./mm) | mm | mm | KG | ||

| 5.5″/DN125 | 133*4.5*3000 | 2.5+2 | SK | NB600+ST52 | 44 |

| 5.5″/DN125 | 133*5*3000 | 3+2 | SK | NB600+ST52 | 49.2 |

| 5.5″/DN125 | 133*5.5*3000 | 3+2.5 | SK | 65Mn+ST52 | 53 |

| Concrete Pump Deck Pipe | Hardened Single Wall | ||||

| DN | Specification | Flange | Material | Weight | |

| (in./mm) | mm | mm | KG | ||

| 5.5″/DN125 | 140*7*3000 | SK | NM50 | 70.7 | |

| 5.5″/DN125 | 140*7.8*3000 | SK | 37Mn5 | 78.7 | |

| Concrete Pump Deck Pipe | Hardened Twin Wall | ||||

| DN | Specification | Wall | Flange | Material | Weight |

| (in./mm) | mm | mm | KG | ||

| 4″/DN100 | 114*7*3000 | 5+2 | SK | NB600+ST52 | 57.8 |

| 5.5″/DN125 | 140*8*3000 | 5+3 | SK | NB600+ST52 | 79.5 |

Please read the below steps to choose a suitable concrete pump pipe. It will get more benefits in your next pumping job.

1. Concrete Pump Pipe

Concrete pump pipe is the pipe that conveys the liquid concrete to the project site, it is the important wear part applied for concrete pumps, concrete placing boom, trailer pumps, and so on, generally, a concrete pump has more than 10 pieces of pipes Because the concrete pump pipes are continuously receive the impact of concrete, it has become the most wearable part of the concrete pump truck. A high-quality concrete pump pipe determines the working effect of the concrete pumps.

2. Concrete pump pipe type:

1) Lay Down Pipe: this pipe is used in trailer pumps, it is commonly made of ST52 and Q235 with a thickness of 3 mm and 6.5mm for less demanding operations. This kind of pipe is not quenched and is usually, for short-term use, Generally, a lay-down pipe is a single pipe and the most widely used concrete pump, SK, HD, MF, and ZX fangle is available.

2) Concrete Pump Boom Pipe: this pipe is used in concrete pumps and placing boom, because the pipe afford the big pressure from the pumps, so the wall thickness more width than the laydown pipe,meanwhile, the materals is durable than ST52, It is commonly made of 45Mn, G500M, G550M, G650M, and chrome carbide lined weld ends, it include hardened single,twin wall and composite concrete pump pipe, the wall thickness from 4mm to 11mm

3) Concrete Pump Deck Pipe: this pipe is used in concrete pumping, it is near the pump truck deck and the weight is bigger than boom and laydown pipe, the material is made of NB600, N400, G500Mand so on, and the wall thickness from 7mm -11mm, both single wall and two is available, all the deck pipe should be handed by heat treatment.

3. How to Get the right Concrete Pump Pipe

1)The first step is to know what kind of machine you use.

every concrete pumps should use suitable concrete pump pipe

Trailer concrete pumps are widely used for everything from shotcrete to self-levelling floor , With a delivery pressure of from 50 up to 80 bar.This machines con This equipment consumes the most pieces of concrete pump pipe,for contractor, For builders, low cost and fast installation are two basic requirements,so the 3-5mm wall thickness ,(whatever,some work sitiation requires 6-7mm wall )3000mm,3048mm,Q235 and ST52 material ,without heat treatment concrte pump pipe is the most popular.

Stationary concrete pumps for all kinds of concrete applications.Distances of more than 2000m and heights of over 600m can be reached.When this machine work ,they need higher working pressure to convey the concrete .Gerenally,this pumps delivery pressure can reach 70 to 110 bar,so the high pressure resistant and lighter concrete pump are the first choice by the contractor. Considering less abrasion,single wall,without hardened and heat trement concrete pump pipe is a good choice.for example,swchwing M/F and Putzmeister ZX concrete pump pipe is something like this,the pressure ressitant can reach 130 Bar.

Truck concrete pumps offers a range between 20m to 68m boom reach and pump performance up to190m³ per hour,so concrete pump pipe of 85 bar working pressure are enough.Whatever,lots of elbows used in this machine which increase more pipe abrasion.Mean while,if the pipe damaged suddenly while the machine is working at the job site,it will take more time and labor to replace a new pipe.Because of that,wear resistant hardened and twin wall concrete pump pipe are better choise to ensure efficiency.otherwise,for saving cost,some people still use the sighle wall pipe on their machine.

2)Get to Know Your Concrete Pump Pipes Working Situation

Working Temperature and Labor Costs

When your pumps work at very hot place,Middle East,Soth East Asia,Africa,lower price concrete pump pipe is their better choise.Because the concrete become solid fast in the pipe as the high temperature.It is diffcult to wash the concrete pump pipe.For saving time ,people in those area are often chang a new one.

Generally,European and North American customers use concrete pump pipe more often than others.Because if use single wall pipes,the change pipes frequency will increase,the labor costs will be added at the same time.high labor costs make them choose more durable twin wall pipe.

Concret Quality

Low quality concret will speed up the concrete pump pipe,secondly, Regular acid rain will also accelerate the corrosion of the pipes, sharp aggregate is also an important reason for accelerating wear.If your machine work in Hubei province,because the aggregate is tough and sharp,the concrete pump pipe serve time is the only the half of other area of China.

In this case, if you don’t want to change your tube frequently, double-layer tube is your better choice

4.Get Your Concrete Pump Pipe Cost Sheet

After understanding the above information, you will know what kind of concrete pump pipe is suitable for your machine. Then you will find that each pipes has a different configuration with different price. Below I will enumerate an optional list of the concrete pump pipe for your reference.

1) Concrete Pump Pipe Wall Thickness

Every concrete pump pipe have different wall thickness which can be used according to specific requirements. Thicker walls mean higher wear resistance, but it also means higher prices and heavier weight.you will get the most widely used wall thickness of concrete pump pipe at jewinnerparts.com

2) Concrete Pump Pipe Flange Type

In order to get the right pipes for your machine,first you should confirm the fange type of your concrete pump pipe. In general, flanges are divided into these four types:HD,SK,ZX and FM.

3) Concrete Pump Pipe Paint Treatment

If you use baking paint,the pipe surface looks more beautiful and smooth,

meanwhile,the pipe hardness will increase,but the price of baking paint concrete pump pipe is more expensive around 1 USD dollar than spray paint pips

4)Package

One 20’’ full container could put 200-300 pieces concrete pump pipe.According to the customer enquirement .we have the package way as below(different montherd have different price).

Make a Purchase Plan

As the most consumble parts of your concrte pump,you should keep the enough pipe s inventory in your warehouse which keep your machine working.

Its better make a purchase plane for quarter time at least.

The concrete pump pipe weight and shape is not convenient for shipping if you only order few pieces.for example,if you order one 80 USD value pipe,may be the shipping cost is more than this value.So buy more pieces at one time is necessary for saving your cost.

5. Know the Service Time of Concrete Pump Pipes

Without hardened single wall pipe less service time than hardened and twin wall pipe,it means boom pipe and deck pipe can use longer time than laydown pipe.jewinnerparts 5mm and 5.5mm hardened twin wall pipe is the most popular pipes in our products family.the pumping volume can reach 60000-80000 cubic meters.

The concrete pump pipe service life can be based on the following 2 factors for your reference

1. The calculation begin from replacing the whole set of concrete pump boom pipes, deck pipes, elbows and other configurations

2. Ensure that the grade of concrete is at least China C30 ,high Grade or with some special aggregates is not avaliable.

But in actual operation, it is difficult to achieve these two conditions at the same time. But this method is still a good way to calculate the service life of the different concrete pump pipe.

6.Get the best suitable concrete pump pipe for your next project

Through the above analysis, you should know how to choose a suitable concrete pump pipe for your pumping work. jewinnerparts has been researching in this field for more than 10 years and has an experienced technical team, which will surely provide you with affordable factory prices with high quality pipes,

Send email to info@jewinner.com,tell us want you want to,Or you can follow us in Instagram:https://www.instagram.com/jewinner_concretepump_parts/

Product Parameters

| Name | Size | Thickness(mm) | Working pressure |

| Schwing M/F pipe | DN125 | 3-12mm | 130-200 bar |

| Putzmeister ZX pipe | DN125 | 3-12mm | 130-200 bar |

| Single wall pipe | DN125 | 3-12mm | 85 bar |

| Twin wall pipe | DN125 | 3-12mm | 85 bar |

| Name | Material | Size | |

| welded concrete pump pipe | Q235 | DN60-DN180 | |

| seamless concrete pump pipe | ST52 | DN60-DN180 | |

| hardened concrete pump pipe | 45Mn2/55Mn/65Mn | DN60-DN180 | |

| twin wall concrete pump pipe | NM600+ST52 | DN60-DN180 |

If you can not find what you are looking for? Just email us: info@jewinner.com the type you want to, we would like to give you full support. Or you can follow us on Instagram:https://www.instagram.com/jewinner_concretepump_parts/